The Foundation of Automotive Safety

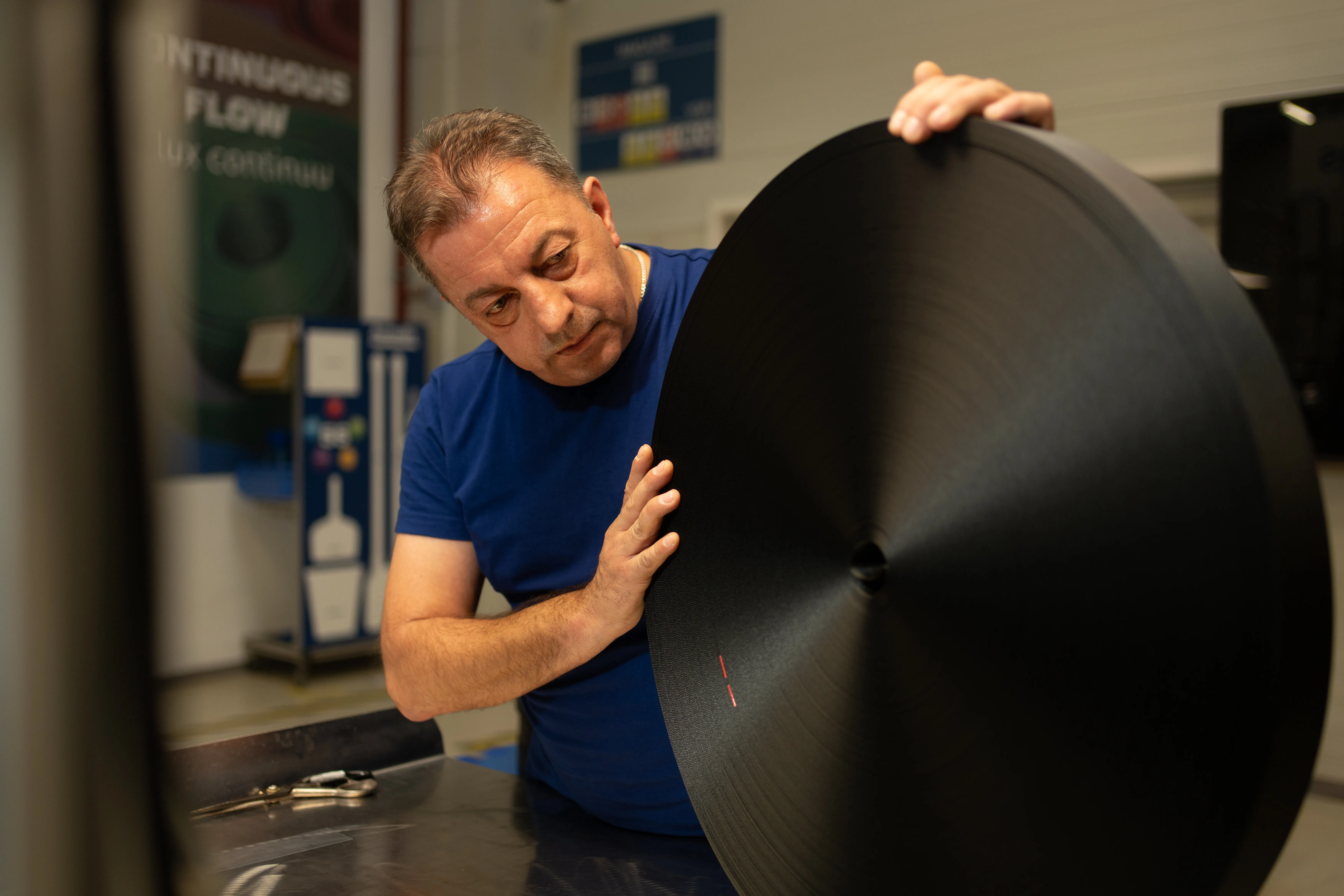

At Autoliv, we know that the seatbelt remains the most effective restraint system ever developed—protecting millions of occupants since its introduction and continuing to be a vital element of crash protection today. A modern seatbelt system is far more advanced than it appears. Behind its sleek design lies a complex assembly of over 140 precision-engineered components, working together to deliver uncompromising safety and comfort. Seatbelt systems are built to perform under extreme conditions, enduring temperatures from -40°C to 105°C without compromise.

Autoliv has been at the forefront of seatbelt innovation for over 70 years, introducing technologies like pretensioners, load limiters, and adaptive systems that significantly enhance occupant protection. Today, Autoliv remains the global leader in seatbelt technology, delivering seatbelt innovations that strengthen our vision of Saving More Lives.

Developing a seatbelt system is a multidisciplinary challenge. It combines mechanics, electrics, electronics, textiles, hardware, software, and even pyrotechnics—all integrated through cutting-edge technologies for design, analysis, testing, and production.

The seatbelt retractor may be hidden, but it plays a crucial role in keeping you safe. Inside this compact high‑performance mechanism, the seatbelt webbing is stored on a rotating spool that smoothly releases the belt when you buckle up and instantly reacts when the vehicle senses danger. As you pull the belt, the retractor ensures a comfortable, effortless motion. In critical driving situations or a collision, its intelligent sensors and safety features work together to protect you within milliseconds.

The seatbelt retractor is designed to deliver both safety and comfort in every drive. It allows the belt to glide smoothly when you buckle up and keeps it neatly stored when not in use. During sudden acceleration, deceleration, or tilting, its car‑sensitive sensor locks the belt instantly—and the webbing‑sensitive sensor does the same if the belt is pulled too quickly.

In a crash, pyrotechnic pretensioning tightens the belt to secure the occupant, while load‑limiting technology helps reduce the risk of severe injuries. Advanced adaptive load‑limiters can even adjust protection based on crash severity and occupant characteristics.

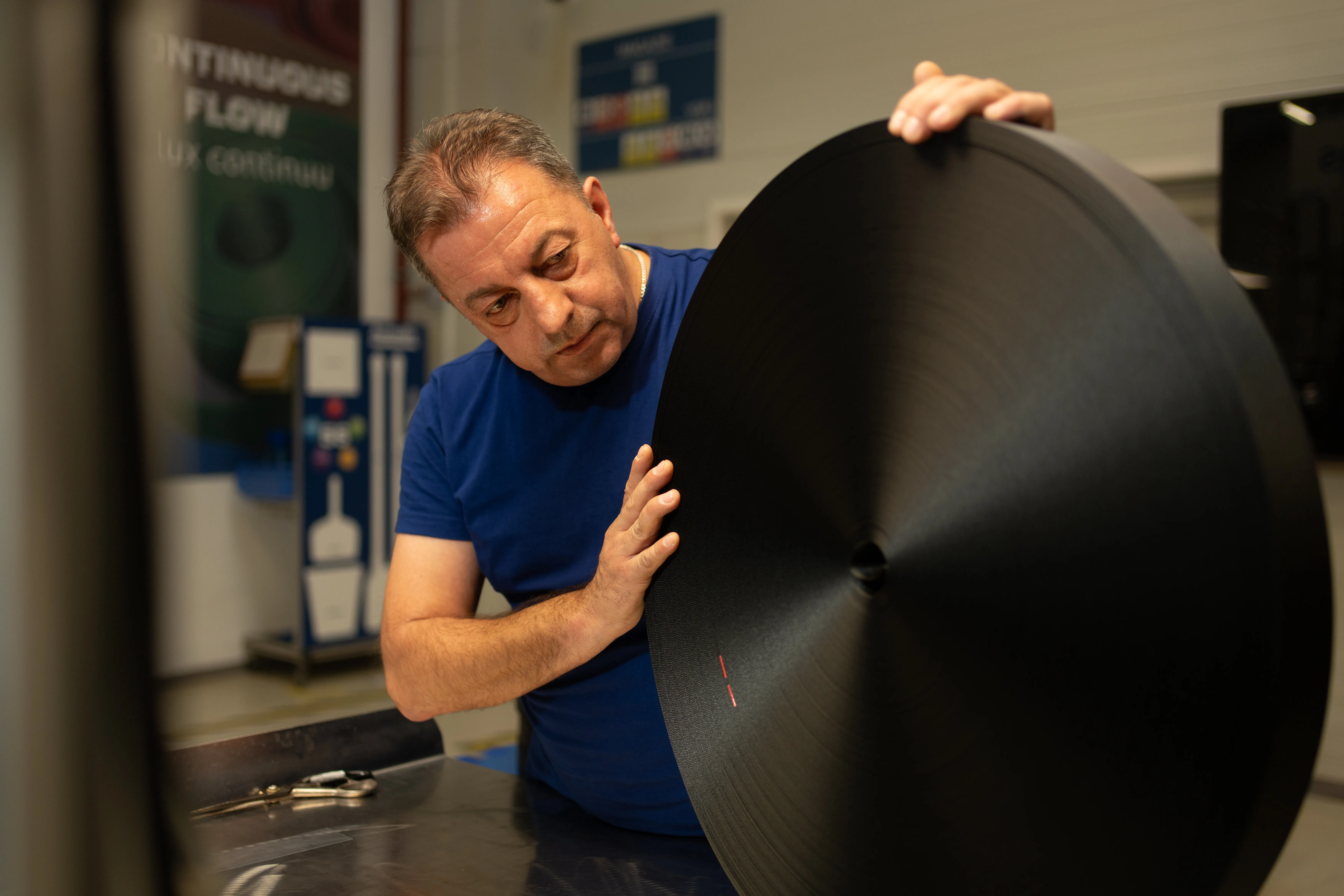

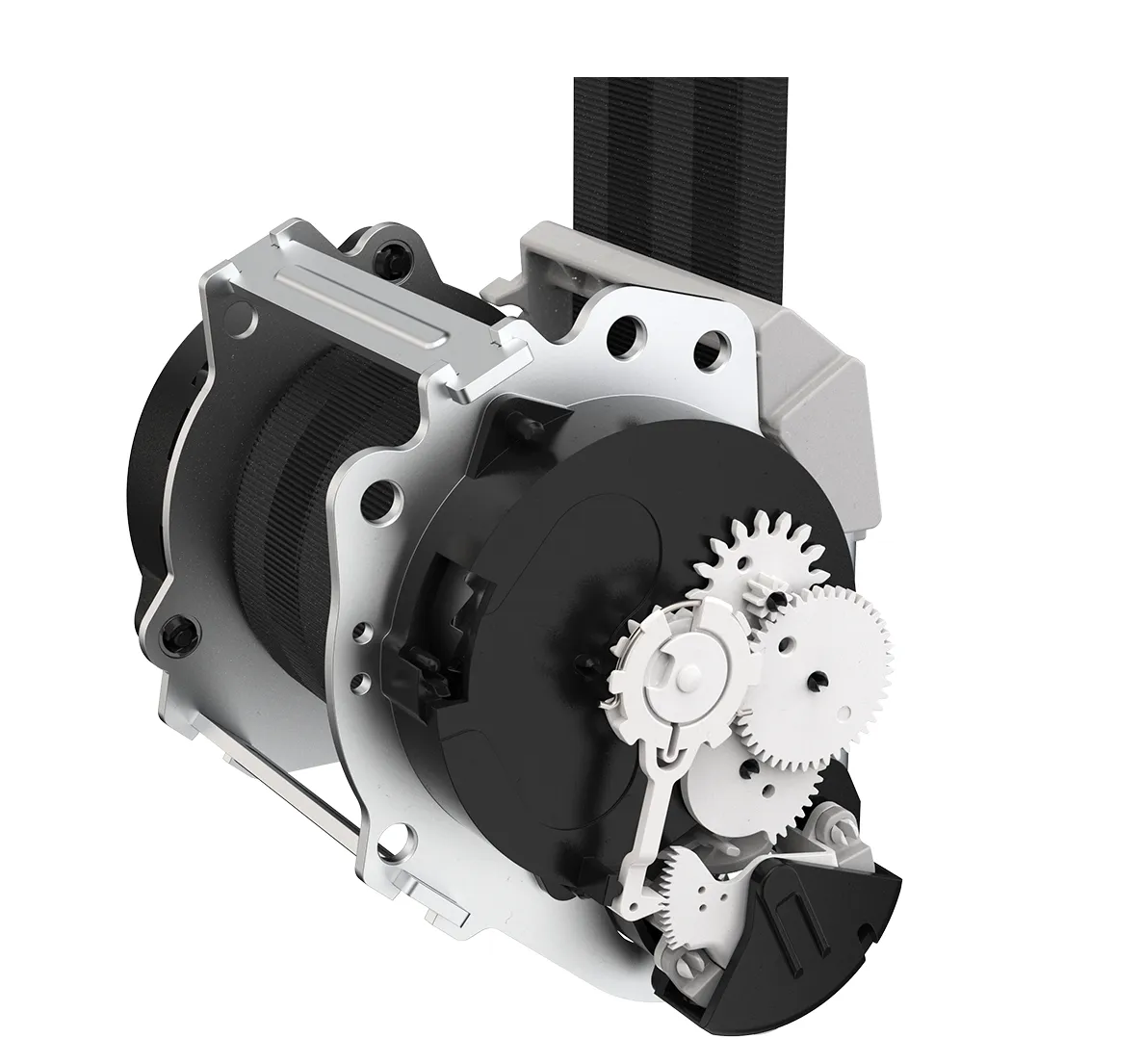

While Retractors and Pretensioners are activated during the crash event, Pre‑Pretensioners operate in the pre‑crash phase as part of the vehicle’s active safety systems. These reversible electromechanical modules receive commands from the safety ECU, which analyzes vehicle dynamics and triggers the system to gently wind up the webbing on the spool. By doing so, the Pre‑Pretensioner removes belt slack and positions the occupant more effectively ahead of a potential crash. This early coupling helps reduce pre‑crash excursion and ensures the occupant is closer to the optimal restraint position.

If a crash occurs, the in‑crash components take over seamlessly. If the critical situation is avoided, the PPMI module releases the tension in a controlled, comfortable manner. As fully reversible systems, Pre‑Pretensioners can activate repeatedly whenever required, based on ECU input.

The module can engage in several pre‑crash scenarios—including heavy braking, ADAS‑initiated Autonomous Emergency Braking (AEB), or vehicle instability such as skidding. Beyond safety, these systems also offer convenience and support functions, such as delivering a haptic warning to alert the driver (for example during lane departure without signaling) or assisting with belt parking by supporting smooth webbing retraction during stowage.

The buckle and tongue form the detachable connection of the seatbelt system, enabling easy fastening and unfastening for the occupant.

Beyond convenience, these components are engineered to deliver critical safety performance during a crash and ensure safe release afterward. Features such as controlled Buckle Opening Force, even in demanding scenarios like side impacts, guarantee occupant protection and post-crash accessibility.

Modern buckle systems can also integrate pyrotechnical pretensioning, providing additional belt tensioning during a crash for enhanced restraint. To meet diverse vehicle designs, buckles and tongues are available in various shapes, colors, and finishes, harmonizing with interior styling.

The Third Point Anchorages are one of the fixation points of a 3-point belt with the car environment. During the crash, they transfer the load coming from the belt to the car chassis and make sure that the occupant is held in place.

These fixations points are either passive components, like brackets and anchors or pyrotechnically active, like the PLPs (Pyrotechnical Lap Pretensioners). The PLPs offer an extended support, to hold the occupant’s pelvis in place and avoid a phenomenon called “submarining”, that causes the occupant to slide from the seat pan and have knee injuries.

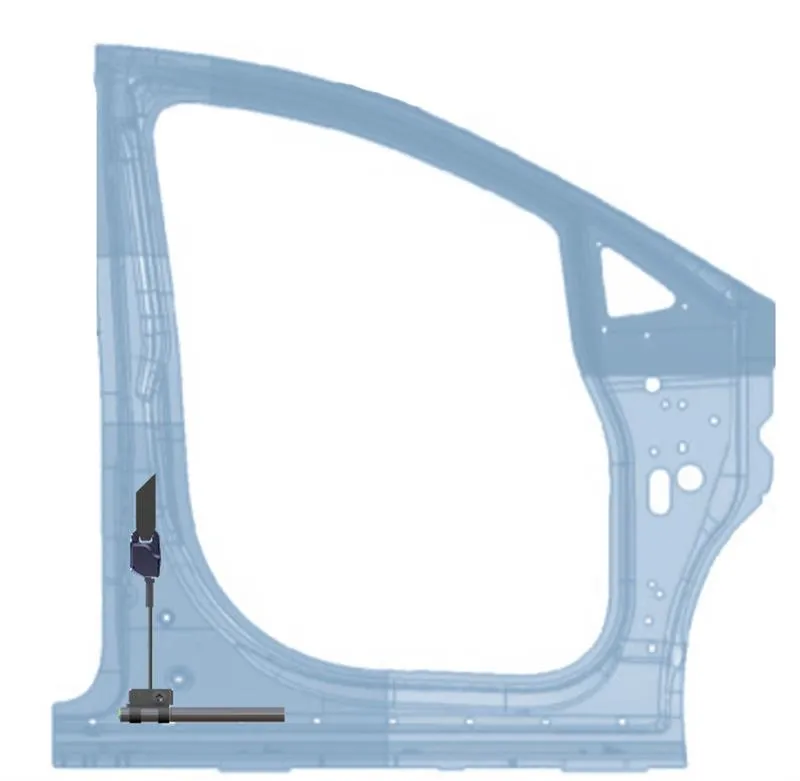

The Height Adjusters are as well a part of the fixation points of a 3-point belt with the car environment. Similar to the Third Point Anchorages, they transfer the load coming from the belt to the car chassis. Their role is to adjust the seatbelt’s D-ring position (the loop that holds and guides the webbing coming out of the car B-pillar) so that the occupant is on one hand comfortable wearing the seatbelt and on the other hand that the webbing’s relative position to the chest is optimal during driving.

Vehicles that do not have Height Adjuster modules offer the similar function through seat pan and seat height adjustments. For those vehicles, the D-ring’s position is fixed in the B-pillar.

Autoliv designs seatbelt systems to accommodate diverse vehicle interior layouts and meet varying safety requirements across global markets.

Seatbelt webbing is the essential link between the occupant and the vehicle. It is engineered to: