Digital business transformation is an integral part of Autoliv strategy

Digitalization, together with a high emphasis on safety and sustainability, is a cornerstone of Autoliv's operational excellence. Automation has been and remains in high focus for Autoliv and contributes to our strong market position.

Becoming the market transformer

Autoliv is on its well-planned journey to transition from the market leader to the market transformer in safety for mobility and society. To enable this journey, we are significantly improving operational efficiency, accomplishing tasks rapidly and at a large scale, optimizing resource allocation and empowering knowledge exchange. We are prepared to be leading the digital transformation journey in automotive and mobility safety.

Securing all-encompassing digital transformation

At Autoliv, we believe that everyone fuels our digital transformation journey. We’re enabling a cultural shift in the organization to speed up the value creation. We have clear priorities and work as one towards the same goal.

We’ve identified key digital transformation initiatives that we consider to be the most impactful at Autoliv. All of these require cross-functional teams working collaboratively and have common agile ways of working to achieve a higher level of effectiveness

Fredrik Westin, Autoliv CFO

AI (Artificial Intelligence) at Autoliv

As a market leader in automotive safety, we believe that AI will play a major role in shaping our business. Therefore, we are constantly researching and exploring the possibilities artificial intelligence can create for us.

At Autoliv, we refer to Advanced Analytics when talking about AI topics, as it provides a broader perspective to the scope of projects we cover with artificial intelligence.

We use AI and machine learning to explore new horizons, improve quality and efficiency. The backbone of AI is machine learning, it’s about looking at existing data and doing something transformative with that information.

Autoliv is significantly increasing investment in AI, we are moving fast to rapidly test new ideas and solutions.

AI & Digital Automation Cases

Seatbelt retractor audio analysis

At Autoliv, we manufacture approximately 150 million seatbelts annually.

The Seatbelt retractor audio analysis, known as "The Sound of Safety," is one of our AI solutions that originated in Mexico, Tijuana facility, and has now been expanded globally within our company.

Previously, we had to test retractors by hand, which was quite a challenging task. But then, we came up with a smart idea: we set up a system that listens for noises and can tell us which parts are making noise all on its own, without needing any human help. We recorded a bunch of sounds and taught the computer to tell the noisy parts from the quiet ones.

Computer Vision

Our company boasts extensive expertise in AI computer vision in quality, applied to more than 70 different use cases. Presently, we are venturing into the next generation of cameras and algorithms, with applications spanning logistics, safety, productivity, and maintenance. We employ this approach both internally and in external open innovation platforms.

Autonomous mobile robots

We've successfully integrated Autonomous Mobile Robots into our primary manufacturing facilities, delivering substantial value. Several are currently in the process of implementation, and we plan to introduce more worldwide in a phased manner. This presents a remarkable chance to eliminate the burden of heavy transportation, reduce time consumption, free up space, and reallocate our workforce to more efficient tasks. Moreover, it greatly enhances safety within our plants and minimizes downtime.

Robots building perfect parts to save more human lives

We've integrated robots globally, and they play a crucial role in our industrial assets for manufacturing safety components and products. One particular robotic solution we're looking to enhance is a close loop feedback mechanism. As we move farther from the desired standard, the robot can autonomously recalibrate to return to the standard, ensuring the consistent production of flawless parts and ultimately contributing to saving more lives.

An excellent example of this is at our Autoliv Inflators facility in Brigham City, where we employ 11 robots in building the parts. Using robots allows us to apply human intelligence in an automated manner, ensuring the creation of perfect parts. The robots do things repeatedly, so they take out variation that human intervention can enter the process. They can also learn from their movements and measurements and create a way to use digitalization and incorporate digitalization to make them better and better with each part they build. We're only beginning to explore the potential here, and there's an opportunity to extend this approach throughout the entire factory.

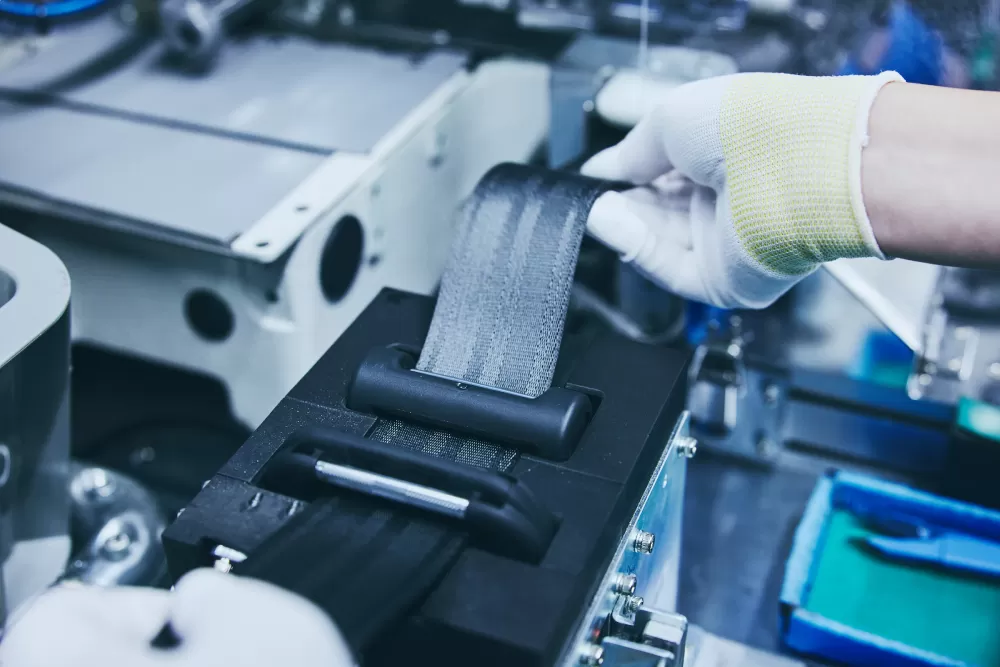

Seatbelt automation

Within our organization, we have implemented a variety of highly advanced production lines that are both fully automated and exceptionally flexible. Moreover, we've introduced numerous in-process automated solutions, further enhancing the precision and reliability of our operations. These innovative systems work tirelessly to optimize every step of the manufacturing process, ensuring consistent quality and allowing us to meet the highest industry standards.

China is a great example within Autoliv, where these principles come to life and revolutionize our production capabilities. We've successfully achieved a reduction in our workforce by anywhere from 30% to 80%. Additionally, we've managed to shorten the cycle time of a particular process, decreasing it from 18 seconds to just 15 seconds. This reduction in cycle time translates directly into increased output.